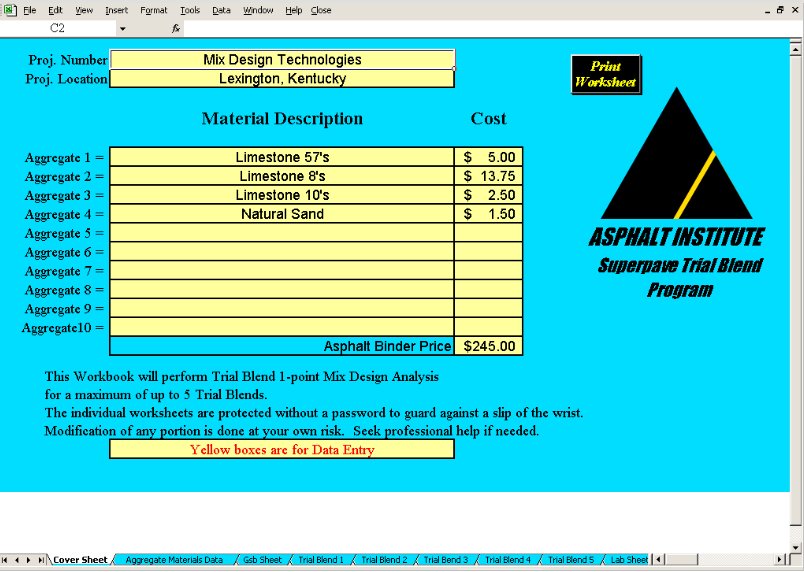

Introduction on PAVERS & pavement design. This concept enables you to exploit all the comprehensive advancements in technology with maximum of ease to use. The User input into future developments and the ability to incorporate new features with strong and functional designs really makes Pavers ® state-of-the-art. Sharing knowledge is essential to innovate and improve the tools and membership of the PAVERS User Group is automatic upon purchase of the system. Hence, the effect of different pavement materials, strengths, load or complex load mixes can quickly be explored. It is a complete software package that allows the modern pavement engineer to define or use calibrated performance models and failure criteria for all pavement layers and subgrade in his pavement design and H/FWD assessment projects. The tool allows to back-calculate FWD-deflections, model the pavement structure, (re-)design the pavement, determine the load-carrying capacity (in terms of ACN/PCN), calculate the remaining pavement life and determine feasible rehabilitation measures. The PAVERS Team strives to make state-of-the-art pavement tools designed specifically for FWD evaluation and Design of road, industrial and airport pavements. Pavers is a premium analytical pavement design and evaluation tool which provides you with an edge over your competition. Create a pavement design, customize it into detail with parameters such as design lane or deviation and save it for later use. Here, the 12.5 mm (0.5 inch) Superpave surface course and the 25 mm (1 inch) dense-graded binder course are structurally equivalent.PAVERS - Premium Pavement Design Software with Powerful Libraries It is interesting to note that in most empirical design procedures HMA, no matter what the specific mix designation or size, is treated equally. Notice also that a change in reliability level from 90% to 99% results in a SN increase of about 1.0 and a resultant increase in HMA thickness of about 55 mm (2 inches). The American Association of State Highway Officials (AASHO) issued its interim guides for the design of flexible and rigid pavements in 19 respectively, following the 19581960 Road Test. In this particular example, which only shows one set of possible solutions, the HMA surface course and base course layer depths were kept constant and the HMA binder course depth was varied depending upon requirements. Layer coefficients used were 0.44 for HMA and 0.13 for crushed stoneįrost design requirements must be checked if subgrade soil frost susceptible Work can be verified by using the Flexible Pavement Structural Design Utility. Truck trains – trucks with more than 2 units (assume 1.75 ESALs per truck) = 247/dayīy looking at several different design periods and reliability levels this example gives an idea of the relative influence of these inputs. Single unit trucks (assume 0.40 ESALs per truck) = 1872/dayĭouble unit trucks (assume 1.00 ESALs per truck) = 1762/day This represents a typical range of reliability levels encountered for Interstate highways. Investigate three levels: R = 90%, R = 95%, R = 99%. M R = 86 MPa (12,500 psi) in the wet months of November through April It is provided on a CD with the textbook (2003 edition). KENPAVE: This suite includes KENLAYER and KENSLAB. M R = 103 MPa (15,000 psi) in the dry months of May through October Pavement Design/Analysis Software Important Note: The following programs can be downloaded and be used by students in CE475 or CE575 for educational purposes only.

Flexible pavement design software free download download#

Use E = 3,447 MPa (500,000 psi)Base course: Crushed aggregate with M R= 193 MPa (28,000 psi)Subbase course: None used Download Pavement Analysis and Design By Yang H Huang The first edition of Pavement Analysis and Design was published in 1993. Surface course: 12.5 mm (0.5 inch) Superpave with E = 3,447 MPa (500,000 psi)Binder course: Dense-graded HMA mix with a nominal maximum aggregate sizeof 25 mm (1 inch). Investigate 20, 30 and 40 year design periods Assume 80% of the loading occurs in the design lane

0 kommentar(er)

0 kommentar(er)